Hybrid construction materials combine biobased, recyclable, and durable components to deliver eco-friendly architecture without sacrificing performance. Learn how they lower environmental impact, expand design possibilities, and meet modern building standards.

The architecture and construction industries are facing a turning point. Climate change, stricter building codes, and growing client demand for eco-conscious design are pushing professionals to rethink traditional materials like untreated wood, steel, and PVC.

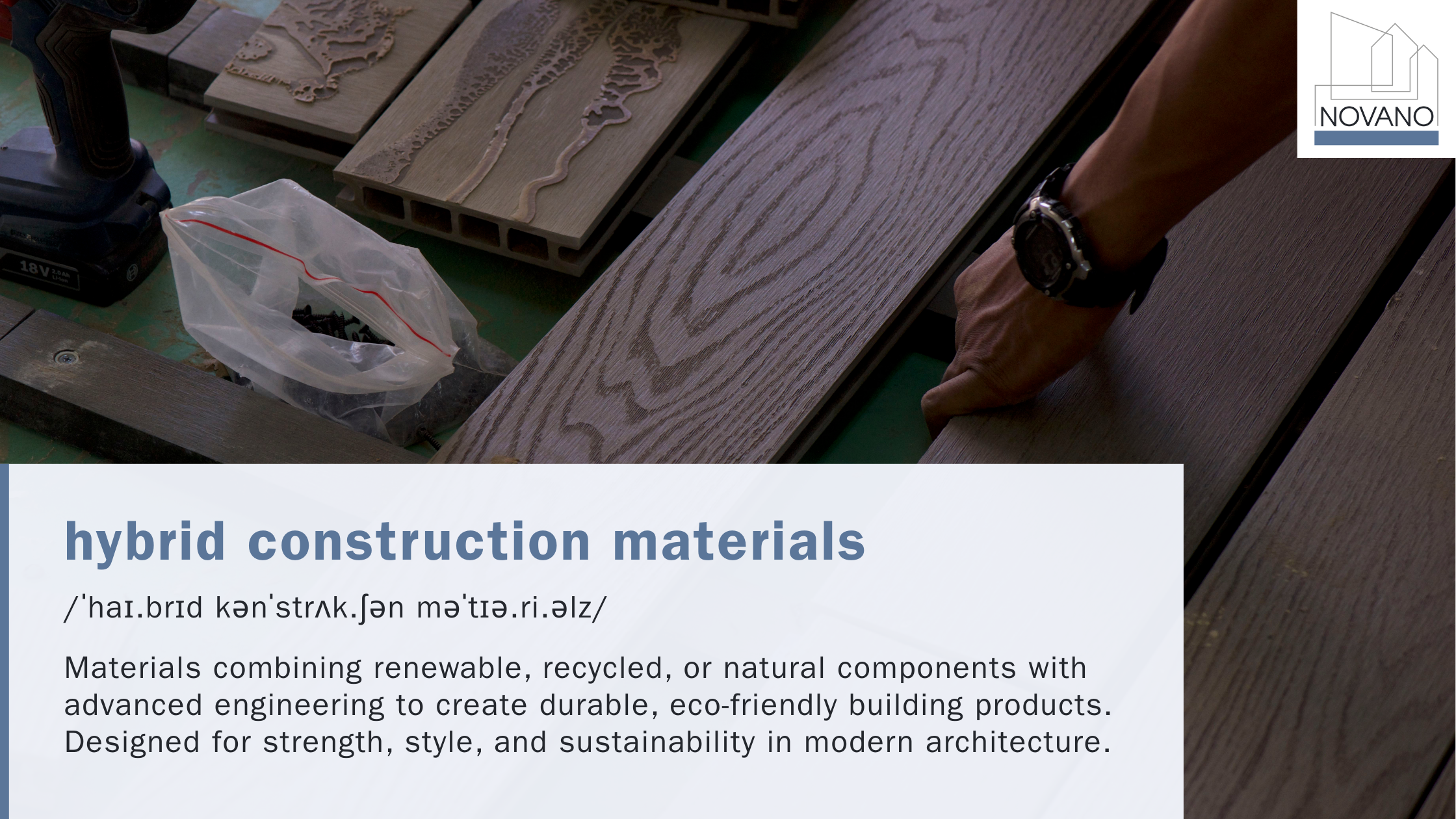

Hybrid construction materials are emerging as a key solution. These materials are made of natural, renewable, or recycled components with advanced engineering to create products that are beautiful, strong, and sustainable.

For US-based architects, developers, and builders, hybrids present an opportunity to design spaces that meet green building standards without sacrificing performance. They also offer the versatility to adapt to a wide range of projects, from urban commercial façades to coastal residential decks, while keeping long-term maintenance low.

According to the U.S. Green Building Council, integrating low-impact materials is one of the most effective ways to reduce a building’s carbon footprint over its lifespan. Hybrid materials provide exactly that, plus the added benefit of design freedom.

✓ Hybrid construction materials combine renewable fibers, recycled content, and advanced engineering to create strong, sustainable building products. They reduce reliance on traditional, high-carbon materials like timber, steel, concrete, and PVC.

✓ These materials are designed for durability, resisting moisture, UV rays, pests, and extreme temperatures. This makes them suitable for diverse climates and long-lasting architectural applications.

✓ Using hybrids can help projects earn green building certifications such as LEED. Their recyclable and low-VOC composition supports environmentally responsible construction practices.

✓ Hybrid materials provide aesthetic flexibility with wood-like textures, modern colors, and custom finishes. They allow architects and builders to achieve design impact without compromising on environmental goals.

Hybrid construction materials combine biobased, recycled, or renewable components to create high-performance building products. Unlike fully synthetic composites, these materials focus on circularity and environmental responsibility.

These materials are designed to be:

The U.S. Department of Agriculture’s BioPreferred Program defines biobased materials as those composed in whole or significant part of renewable agricultural or forestry products. Hybrids often exceed these minimums, offering both environmental and performance advantages.

Hybrid materials reduce environmental impact in multiple ways:

Hybrid materials are completely wood-free, helping preserve forests and prevent deforestation while still delivering the natural look and feel that many architectural projects require. They are made from pure organic, natural resources, ensuring sustainability without sacrificing performance or aesthetics.

They repurpose natural waste materials such as rice husks and plant fibers, reducing landfill waste and supporting circular economy principles.

They typically have a smaller embodied carbon footprint compared to concrete, steel, or vinyl siding. This means fewer greenhouse gas emissions during production and transportation.

Many hybrids resist mold, rot, and insect damage without relying on chemical treatments. This reduces harmful runoff and improves site safety.

End-of-life recovery is built into the product lifecycle, allowing materials to be reused or repurposed. Even production scraps or crumbs can be collected and recycled, ensuring maximum resource efficiency.

They maintain strength and appearance in extreme weather, making them ideal for diverse U.S. climates, from humid Southeast coasts to arid Southwest deserts.

The U.S. Environmental Protection Agency (EPA) highlights that using sustainable materials in construction reduces waste, conserves resources, and promotes energy efficiency. Hybrids fit squarely into this framework.

Hybrid construction materials open up creative possibilities for architects and builders:

NOVANO Building Products USA specializes in advanced hybrid composite materials designed for both beauty and performance. Our composite decking, cladding, and siding collections capture the rich texture and warmth of natural wood while being completely wood-free.

Made from renewable and recycled components, Novano products deliver long-lasting durability with minimal maintenance. They resist moisture, UV rays, and pests, ensuring your project retains its aesthetic appeal year after year.

Get FREE Samples today and experience the quality, texture, and craftsmanship of NOVANO hybrid composites for yourself, or Shop Now as NOVANO launches its new online shop for nationwide access.

Hybrid materials are flexible enough to fit many project types:

Hybrid construction materials represent a balance between nature, performance, and smart engineering. They enable architects, developers, and builders to deliver projects that look stunning, perform under pressure, and contribute to environmental goals.

NOVANO Building Products USA offers a full range of hybrid decking, cladding, and siding designed for modern architectural needs. Get your FREE Samples to see Novano’s quality up close, or Shop Now with our new online store offering nationwide access: https://novanousa.com/shop/.

They are typically made from natural fibers, agricultural byproducts, recycled biopolymers, and mineral blends engineered for durability and low environmental impact.

Yes. High-quality hybrids are designed to resist moisture, UV rays, pests, and temperature changes, making them suitable for all climates.

Yes. Many qualify for LEED points due to their renewable content, recyclability, and low carbon footprint. Their sustainable sourcing and durability also support long-term environmental performance goals.

They work for façades, siding, decking, soffits, canopies, and modular construction projects. Their adaptability makes them suitable for both new builds and renovations across residential, commercial, and hospitality sectors.

They typically require only occasional cleaning, without sealing or painting. This low-maintenance quality helps reduce lifetime costs and labor for building owners.

Error: Contact form not found.